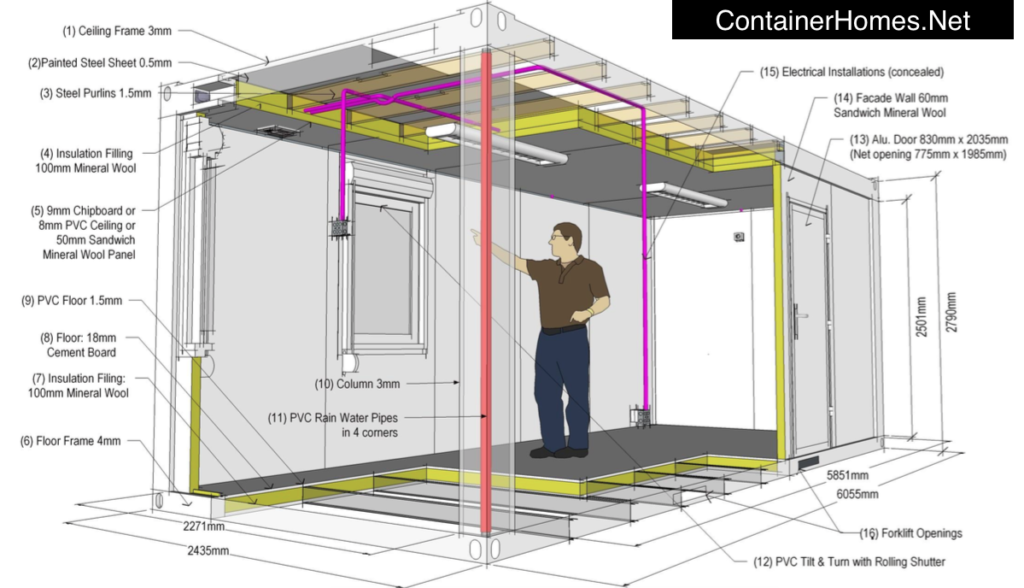

Dimensions and Specs on the Emergency Shelter Homes:

DIMENSIONS and TARE (ISO Standard 1161)

- External length 20’/ (inner length) 20’: 6.055m/(5.851m)

- External width/ (inner width): 2.435m/(2.231m)

- External height/inner height: 2.790m/(2.510m)

- Tare: 1950 Kg

STEEL FRAMEWORK

- Material: cold formed steel profiles in a thickness of 3 to 4mm (bottom rails).

- Surface working: shot blasting, epoxy ground coat in a thickness of 30μm, final vinyl acrylic coat in a thickness of 60-70μm.

- Fittings: 8 corner fittings (dimensions according to ISO standard 1161), rainwater pipe in the roof framework, plate thickness of 10mm excluding

top corner fittings of the top kit of each bundle (20mm thickness)

FLOOR COMPOSITION

- External wainscot: flat galvanized steel sheet metal in a thickness of 0.5mm.

- Insulation filling: noncombustible mineral wool in a thickness of 100 mm among hollow steel transverse supports. Mineral wool density: 50Kg/m3

- Steam blockade: PE foil in a thickness of 80μm

- Plywood floor in a thickness of 18 mm

- PVC flooring covering in a thickness of 1.5mm

- Reaction to Fire Classification: A1 certified ISO EN 13501

- R value (Thermal Resistance) = 2.2 m2K/W

CEILING COMPOSITION

- 6 mm thick corrugated “ISO” roof, CORTEN made, and shot blasted & painted.

- Insulation filling: noncombustible mineral wool in a thickness of 100mm among a double layer of 30X50X2 mm steel square bars. Mineral wool density: 60 Kg/m3

- R value (Thermal Resistance) = 2.2 m2K/W

WALLS

- Side panels’ width: 1140mm; total panel thickness: 60mm

- Galvanized and painted steel sheet metal in a thickness of 0.5mm, white color

- Insulation filling: Mineral wool in a thickness of 60mm

- K value: 0.71 W/ m2K

DOORS

- Steel door, width: 820 mm; height 2000 mm; thickness: 70 mm.

- Composition:External frame: galvanized and painted steel profiles, thickness 0.7 mm

- Galvanized and painted steel sheet metal in a thickness of 0.7mm.

- Equipped with 3 hinges, lock and anti-burglary flange.

- Insulation filling: non-combustible mineral wool in a thickness of 50mm. Mineral wool density: 60 Kg/m3

WINDOWS

- Option 1. Made of PVC, white color, 800 to 900 mm× 1100 to 1200mm.

- glazed with double layer glass in a thickness of 4/15/4mm, with “tilt & swing”

- Mechanism with aluminum made rolling shutters

- Option 2: ALU sliding windows 800 to 900 x 1100 to 1200 mm and ALU rolling shutter

- Fly screen, burglar bars and internal shades available. 8

ELECTRICAL INSTALLATIONS

- Standard: CE, UL, SAF, AUS

- Voltage: 220 V, 50 Hz single or three phase or 110 V 60 Hz single phase.

- Network connections: suitable-connection plug/socket, 3-5 poles 32 A +, 220V~ (110 V single phase only), mounted on the top frame in upper corners of a shorter side wall.

- Inner distribution system: cables of suitable dimensions (6, 2.5, 1.5 mm2 for 220 voltage or double sized for 110 voltage) , flush-mounted.

- Protection: protective current switch (40 A +/2E/4E-0,03A), automatic fuses (C-characteristics) of suitable power (6A, 10A, 16A, 20A)

- Earthing: galvanized connector with a steel plate of dimensions 30x80mm welded on the bottom frame.

- Fittings: Electric distribution box – 1×40A+/2E/4E-0.03A (protective current switch), 1×10A & 2×16A as standard lay out (automatic fuses)

- Double fluorescent lights 2×36W 220V– 2 each Philips IP 65 rated

- Option:”PRC” neon lights IP 65 rated

- Flush-mounted sockets 220 V/110 V – 4 each

- Flush-mounted switches 220 V/110 V – 1 each

POSSIBILITIES OF CONTAINER MOUNTING

On a flat solid surface (asphalt, concrete,)

On point foundations (concrete cubes, dimensions 30/30/30cm, 6 pc/20’ container)

On band foundations (concrete band, 30cm wide, on the container circumference) Certification: Dimensions, weight, payload and stacking are RINA certified. Certificates available for components.

*Delivery: Containers can be delivered assembled or individually – in kits 648 mm high.4 kits can be bundled in packages 2591 mm high